New Energy Lithium-ion Battery Testing

Over the past decade, driven by the development of electronic products, electric tools, automobile and renewable energy, electrochemical energy storage has been developed with an unprecedented speed. Lithium-ion battery plays an important role in transforming stored renewable energy into electric energy. Lithium-ion battery is a significant part for today’s new energy development, especially the development of EV. It could be said that lithium-ion battery is the “heart” of EV. The purpose of battery test can be summarized in two aspects:

1.To understand the characteristics of lithium-ion battery (from the perspective of lithium-ion battery): we need to understand the capacity, internal resistance, voltage characteristics, rate characteristics, temperature characteristics, cycle life, energy density and other important parameters of lithium-ion battery through tests; we need these parameters to assess if the measured battery fulfills the initial design goals, and we also need them for better battery management and control during its usage.

2.To assess the strength of battery to meet the demand (from the perspective of application scenario): these tests can be considered that they are carried out from the perspective of application requirements, and from there the characteristics the battery should have can be derived. Whether the battery meet the standards can also be verified through such tests. For example, auto makers would design the cold cranking amps (CCA) test based on the driving scenario at low temperature, the energy efficiency test based on energy consumption indicators and the power performance test based on when the vehicle is climbing or accelerating. In addition, from the perspective of automobile safety, charge/discharge, short circuit, over-temperature, crush and penetration and other tests are designed.

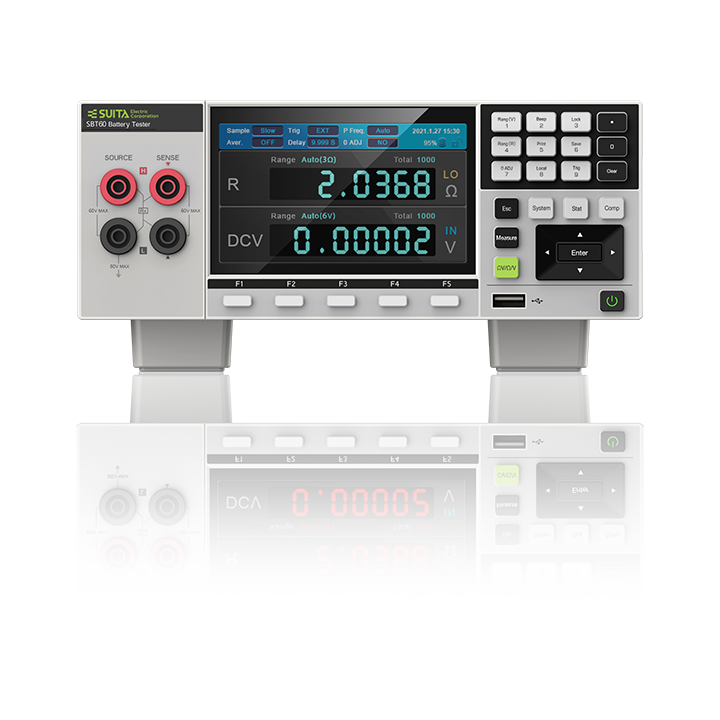

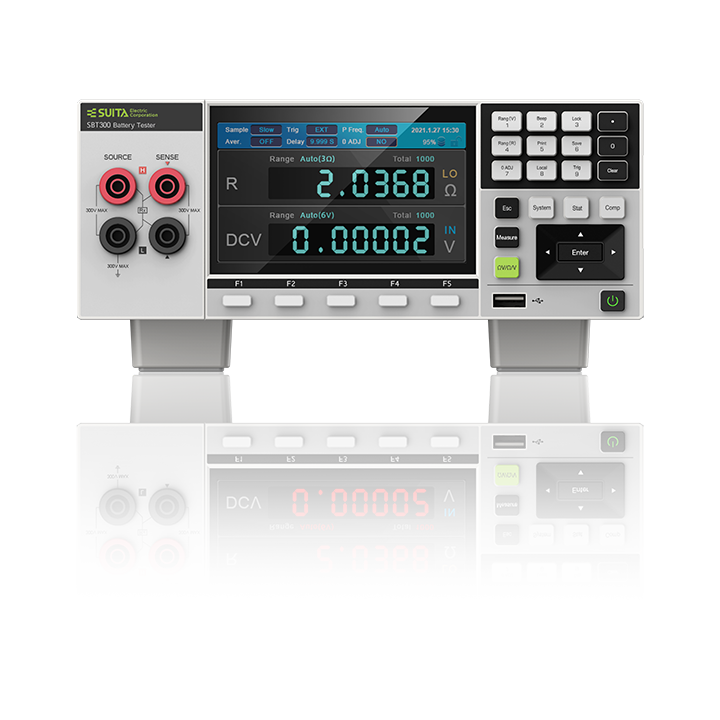

SBT60/300 Battery Tester is a high precision and resolution battery tester. It is widely used in tests for cell phone lithium-ion battery, accumulator, power battery and other batteries. The AC four-terminal test method is adopted for more accurate measurement of battery internal resistance and voltage. The built-in comparator function can automatically assess if the battery parameters meet the standards in order to calculate the pass rate, which is suitable for battery test and sorting. It offers independent comparison function for battery resistance and voltage to make a Pass/HI/IN/Lo judgment. The judging result is shown on the screen and the tester also offers a buzzer and external I/O terminal. The judging results of both sides are displayed on the screen. In addition to the respective judging result of resistance and voltage, the comprehensive judging result can also be outputted through the external I/O terminal.